Reasons for Cell Factory Surface Treatment

The cell factory plays an important role in the large-scale cultivation of cells, and has low risk of contamination. It can utilize the maximum cultivation area in a limited space, save a lot of factory space, and reduce the cost of quality control and downstream purification of the enterprise. cost advantages. This kind of culture consumables generally needs surface treatment before it can be used for cell culture. Why?

According to different growth modes, cells are divided into adherent cells and suspension cells. The growth of such cells must have a support surface that can be attached, and the cells rely on the attachment factors secreted by themselves or provided in the medium to be on the surface. Growth, propagation, and suspension cells are not required. The cell factory is made of polystyrene raw material, which itself is hydrophobic, which is not conducive to the growth of cell attachment. Therefore, it needs to be modified on the surface to become hydrophilic before it can be applied to the culture of adherent cells. This modification method is called TC treatment.

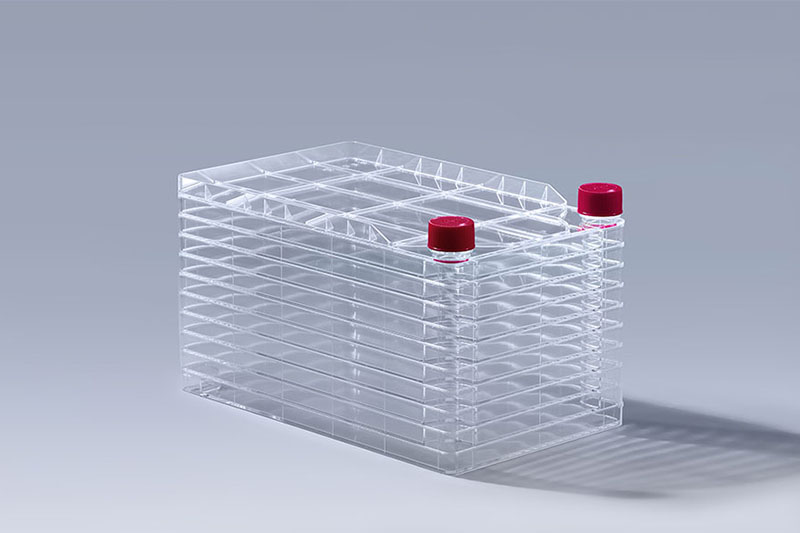

FuDau 10-Layers-Cell-Factory-TC-Treated

The full name of TC: Tissue culture treated, TC treatment means that the vessel has undergone surface modification and is suitable for the cultivation of adherent cells. Cells growing in suspension do not necessarily require such specially treated vessels, but cell culture flasks after surface modification are generally suitable for the cultivation of suspension cells.

FuDau 40-Layers-Cell-Factory-TC-Treated

In summary, the surface treatment of cell factories is mainly to better adapt to the growth of adherent cells. Whether it has been surface treated or not is also a major factor we need to consider when choosing cell culture consumables.

评论

发表评论