Application of Cell Factory Systems in Production of Inactivated Vaccine

Cell factory systems are a common cell culture tool during the preparation of inactivated vaccines. It adopts a multi-layer structure design, which not only takes up less space but has a large cultivation area, and can realize automatic operation with the help of special equipment. Do you know where this container is mainly used in vaccine preparation?

Inactivated vaccines are made by culturing viruses on a cell matrix, and then using physical or chemical methods to kill infectious viruses while maintaining the integrity of their antigenic particles, making them lose their pathogenicity but retain their antigenicity.

Inactivated vaccines can be composed of whole viruses or bacteria, or they can be composed of their split fragments as split vaccines. The inactivated vaccines currently used in China include inactivated polio vaccine, Japanese encephalitis inactivated vaccine, influenza vaccine, rabies vaccine, hepatitis A inactivated vaccine, EV71 hand, foot and mouth disease vaccine, new coronavirus inactivated vaccine, etc.

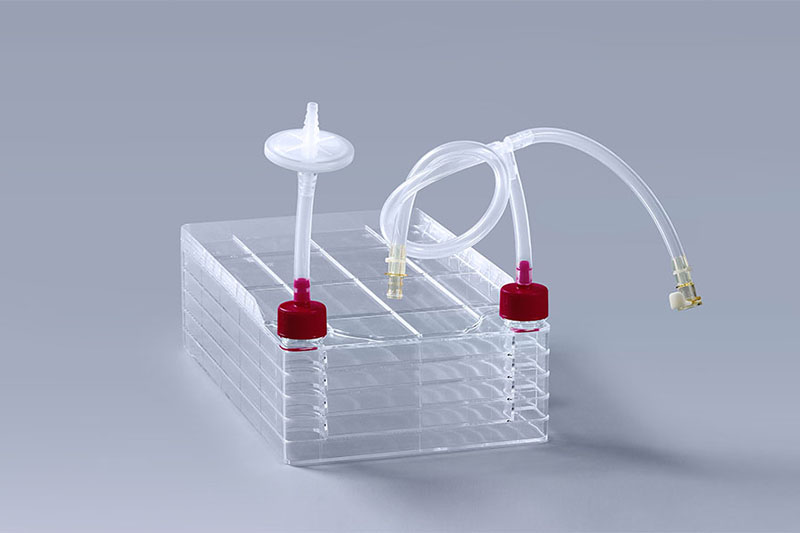

Cell factory systems are mainly used in cell culture or virus culture in vaccine preparation. In the early stage of small-scale culture, 1-layer, 2-layer, and 5-layer, 10-layer containers are mostly used. In the later stage of commercial production, 40-layer factories will be used, to harvest more cells and improve efficiency.

In general, the application of cell factory systems in vaccine production is very mature. In order to prevent external contamination during operation, it can also be equipped with corresponding pipeline systems to achieve sealed transfer of liquids, making the entire vaccine production process more efficient and stable.

Cell Factory Systems

Cell Factory Systems

评论

发表评论