Cell factory systems help the development of the biomedical industry

In recent years, the biomedical industry has ushered in unprecedented development opportunities. In this wave of rapid change, a revolutionary technology has attracted widespread attention, and that is the cell factory systems. As a representative of a new generation of biopharmaceutical production process, it opens a new situation for large-scale production of high-quality biopharmaceuticals.

Traditional biopharmaceutical production processes often rely on tedious cell culture techniques that are time- and resource-intensive. However, the emergence of cell factory systems has completely changed this phenomenon. It uses engineered cell lines and advanced automation technology, which greatly simplifies and speeds up the production process of drugs. By optimizing cell culture conditions, controlling culture parameters and implementing fixed-point detection, a large number of consistent biopharmaceuticals can be efficiently produced, providing strong support for the pharmaceutical industry.

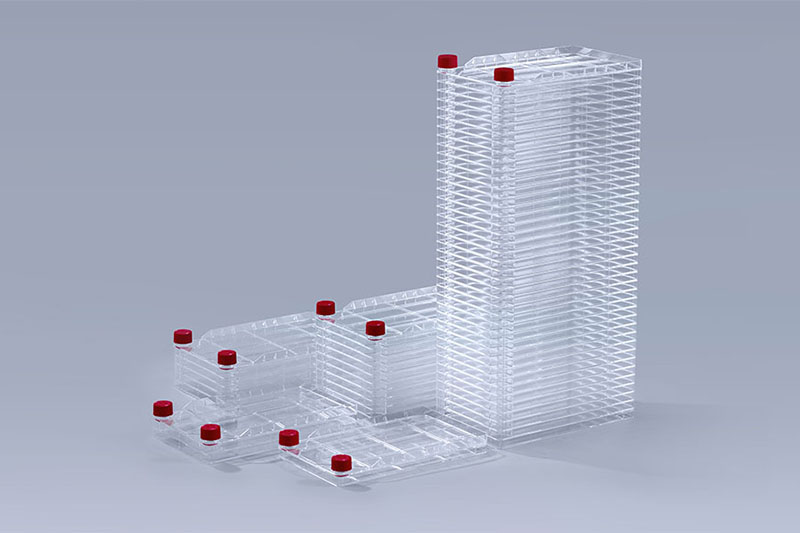

The cell factory systems adopts a special multi-layer structure design, which can maximize the use of space, thereby saving a lot of factory space, manpower and material resources. It can be used in combination with automatic operation equipment to realize automatic cell culture, greatly reducing labor intensity and intensity. It can also use the supporting pipeline system to realize the closed transfer of liquid, reduce the risk of extracellular contamination of cells, and improve operational efficiency.

In short, the cell factory systems, as a common tool for large-scale cell culture, can save plant space and reduce the risk of exogenous contamination of cells. The emergence of this tool will help the better development of the biomedical industry.

评论

发表评论